Secure printing solutions for automobile maker

I. Customer Profile

XX Automobile Co., Ltd, of an annual production capacity of 500,000 vehicles. The 1.6 million㎡ floor area is divided into production lines and office area with a printing zone, with approximately 200 pieces of equipment and a headcount of over 8,000.

II. Background and Status Quo

The printing management system features a typically Japanese granularized management. The obsolete equipment of high failure rate cannot meet the demand for printing management as business grows,

III. Customer Vision

Integration of printing equipment in various zones, elimination of obsolete equipment, deployment of roaming printing based on card-swiping with centralized access management and device status monitoring. Deployment of servers of high availability with on-premise routine services provided by professional engineers and on-duty staff at all times.

IV. Solutions

Complete manageability of printing devices guaranteed with mature and stable printing solutions integrated with roaming printing, photocopying and scan-to-me functions as well as device status monitoring and alert. The offline printing function allows users to print even in the case of server failure, hence ensuring business continuity.

1. System Architecture

Adoption of HA architecture at the headquarters and distributed deployment from remote locations, User may still use printing equipment even in the case of failure of remote node servers,

2. User Verification

AD synchronization allowing for custom synchronous field setting for full synchronization. No card binding is necessary for user, who, once authorized by HR, may directly use printer by swiping the card.

3. Equipment Operation and Maintenance

Smart worksheet management and quick response through connection with user’s first-line service platform.

All-dimension monitoring of device status allowing for threshold value setting for remaining toner, active notification of alert messages and active emergency response mechanism of stock-up / toner replacement.

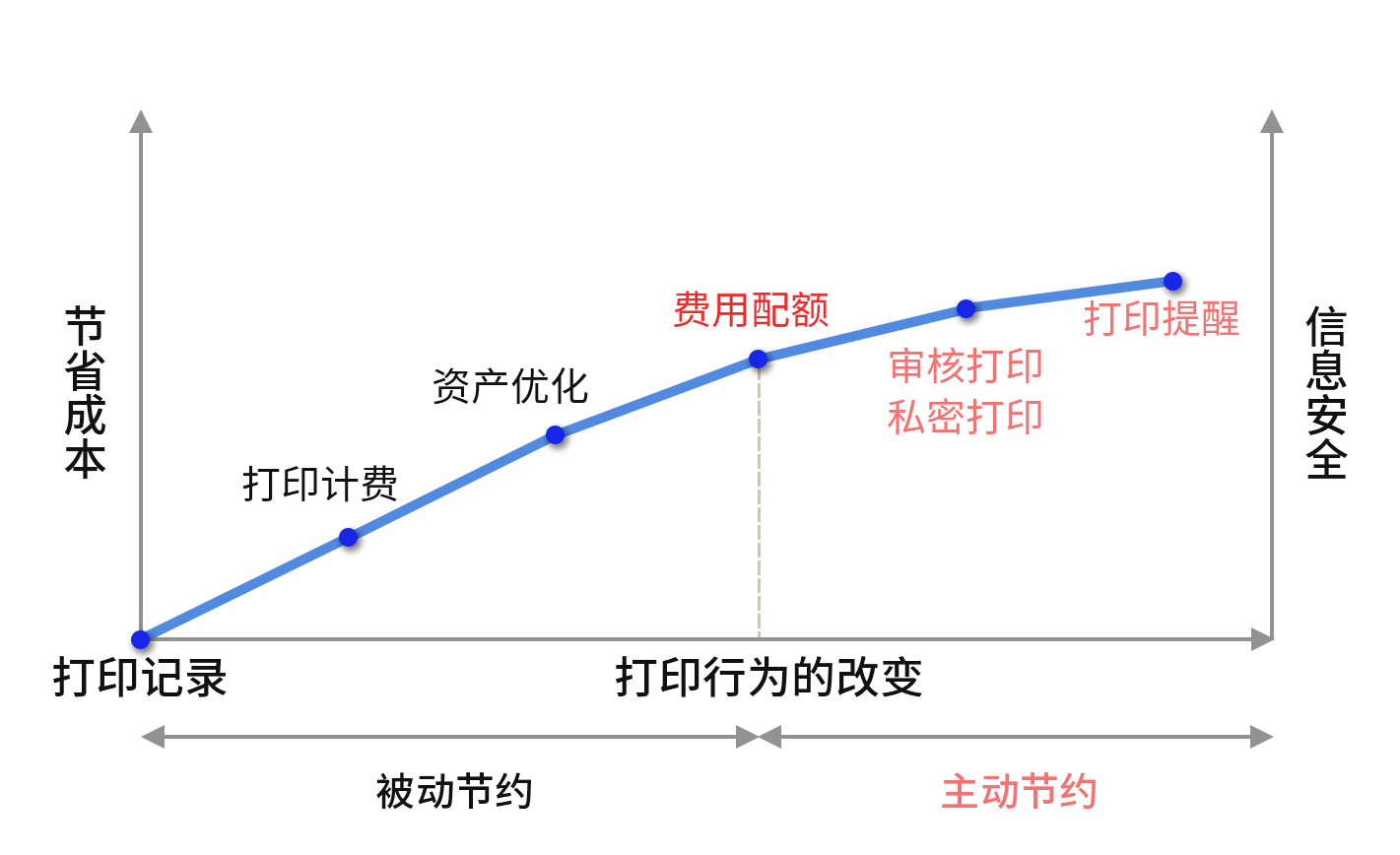

4. Cost Control

Maximizing the utilization of existing facilities through printing equipment integration and elimination of obsolete devices

Mandatory requirement for black-and-white printing for certain departments to reduce cost

Provide diverse report styles of multiple dimensions such as user, department and equipment to provide supporting data evidence for financial cost analysis

5. Risk Control

Backup machine provided for core departments for immediate replacement when recovery from equipment failure is not possible within a short time

Daily routing inspection of server log and equipment status for timely troubleshooting

Automatic switch to emergency printing mode in the case of disconnection or shutdown of node server to ensure continuity for users

Troubleshooting and emergency response plan developed in advance for immediate response and recovery in the case of major technical failures

6.Software Customization

Linked to HR database for customized development and real-time retrieval of users’card numbers.

V. Customer Value

Provide professional service team based on project, featuring fast problem-shooting and efficient service

Reduce total number of equipment by 20% allowing for more printing tasks in public area, economizing office space and reducing energy consumption of equipment

Outsource services to optimize the procedures of equipment maintenance and consumables procurement while cutting the labor cost for equipment management

Software-enabled delicacy management of equipment and personnel, file confidentiality management and cost sharing

Achieve cost reduction and better financial performance, better energy efficiency and emission reduction, eco-friendliness and information security